Inside the humming heart of every modern business lies the IT closet—a central hub powering networks, communications, and digital operations. While often overlooked, the level of organization inside these small yet powerful spaces can directly affect network efficiency, maintenance time, and even security. One of the most underrated methods of maintaining order in these high-traffic zones? Cable labels and color coding.

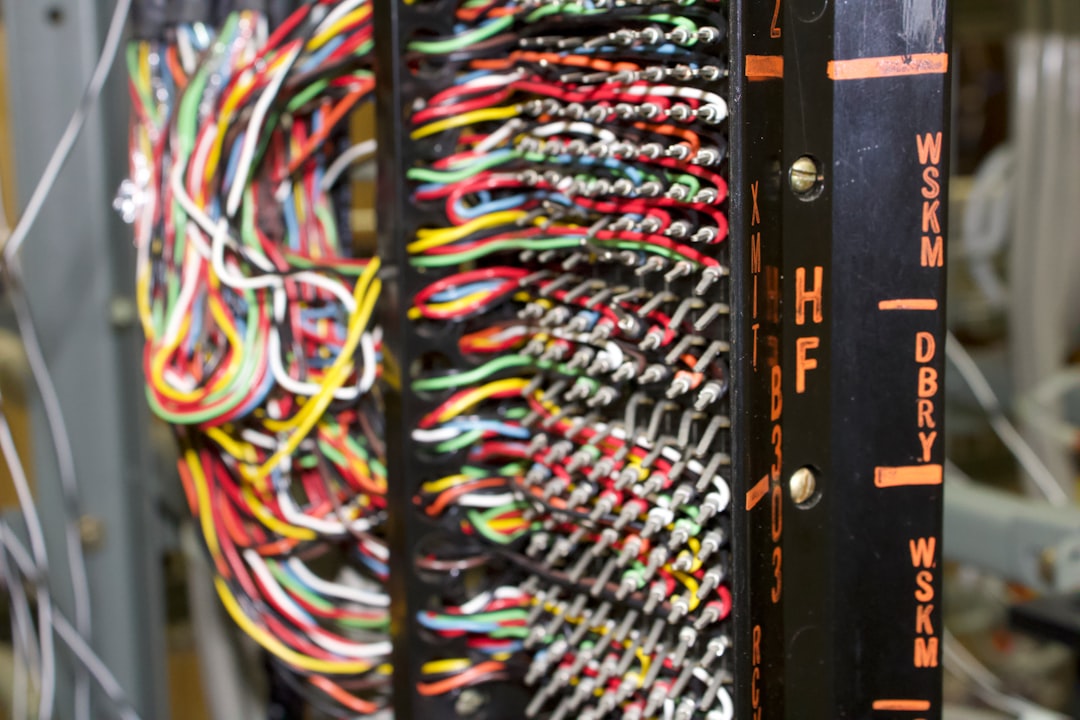

Without a structured labeling and color scheme, an IT closet can quickly devolve into a tangle of mystery wires. Technicians spend countless hours tracing cables back to their source, risking incorrect disconnections or unnecessary downtime. But with a clear, standardized labeling system and sensible use of color, teams can transform their chaotic cabling into a well-oiled machine of connectivity.

The Importance of Cable Labeling in IT Closets

Imagine trying to identify a single Ethernet cable among hundreds, each running crisscross across switches, patch panels, and hardware. Without proper labels, every physical change becomes a time-consuming endeavor.

Cable labeling provides:

- Quick Identification: Labels let you find the right cable at a glance, significantly reducing troubleshooting time.

- Error Mitigation: Clearly marked cables reduce the risk of accidental disconnections or incorrect terminations.

- Maintenance Efficiency: Technicians can work faster and with more accuracy when systems are clearly marked.

- Better Documentation: Labeled cables correlate with network maps and diagrams, improving administrative tracking.

Whether you’re managing a server rack, patch panel, or switchboard, each cable should be labeled at both ends. The goal is to make unplugging and rerouting as clear and safe as possible.

Types of Cable Labels

There are several different approaches to cable labeling depending on your budget, environment, and the permanence of the installation:

- Pre-printed adhesive labels: These come in rolls or sheets and are ideal for larger installations. They offer clean, professional-looking finishes and are easy to apply.

- Handwritten labels: Suitable for smaller setups or emergency fixes. However, they’re prone to smearing and illegibility, especially if not written with permanent ink.

- Wrap-around labels: These labels wrap entirely around the wire and often include a clear tail that seals and protects the label text.

- Flag labels: These labels stick out from a cable like a flag, providing more room for text, though they’re less streamlined in tightly packed racks.

- Heat shrink tubing: Offers a secure, durable way to permanently identify cables, especially in high-heat environments.

For durability and legibility, many organizations prefer to use thermal transfer printers loaded with industrial-grade label stock. This ensures that labels remain intact even under intense heat or vibration—common conditions in an IT closet.

Labeling Best Practices

When it comes to labels, consistency is key. A clear standard helps anyone—be it your in-house team or a third-party technician—understand and navigate the network with ease. Some common best practices include:

- Use a standard naming convention: Label cables according to their function and endpoints, such as “SW1-P24 to SRV-03”.

- Label both ends: Each cable should have identical labels on both ends to aid in tracing.

- Avoid abbreviations (unless standardized): If you’re going to shorten names, make sure your team sticks to the same abbreviations throughout.

- Print legibly and permanently: Use a label maker whenever possible to produce clean and durable labels.

- Update when rerouting: If a cable is moved, be sure to relabel immediately to prevent confusion down the road.

Over time, dust, heat, and human contact may wear down even high-quality labels. Periodic audits of your cable labeling system can prevent issues before they cause real damage.

Color Coding as a Visual Shortcut

While labels deliver details, color coding offers instant recognition. Color-coded cables or cable ties can allow technicians to identify cable categories or destinations at a glance, especially when dealing with large trunks or bundles.

Common uses of color coding include:

- Network segregation: One color for internet connections, another for VoIP, and another for security cameras, and so on.

- Cable function: Use blue for patch cables, red for backbone connections, green for management interfaces.

- Priority levels: Differentiate between mission-critical systems and less essential infrastructure.

- VLANs or subnet allocation: When managing large switch configurations or data flow paths, colors can map to different virtual networks.

It’s important to document your color coding system and make it part of your IT policy. Clear visual guides posted inside the IT closet can reinforce the standard for all staff members.

Combining Labeling and Color Coding

Even more powerful than either system on its own is combining labeling and color coding. For instance, a red Ethernet cable (signifying firewall traffic) labeled “FW01 to SRV-DB02” lets you know in seconds what the cable does and where it goes. Multiple systems working together increase efficiency, clarity, and future-proofing.

In high-density environments like data centers or corporate telecom rooms, combining colors and labels is often essential. As systems evolve and grow, well-documented and visible identifiers make scaling and adapting significantly smoother.

Tools and Supplies for the Job

Getting started isn’t expensive or difficult, but investing in the right gear can make a significant difference. The following tools will help you create a clean, legible, and long-lasting cable management system:

- Commercial label printer: Brands like Brady, Dymo, and Brother offer compact, reliable printers designed for network labeling.

- Label stock: Make sure to get the right kind for your printer, especially if you plan to use heat shrink or self-laminating materials.

- Color-coded cable ties or sleeves: Inexpensive yet invaluable for defining groups visually.

- Cable management trays: Routing cables through trays helps maintain order and visibility for both labels and colors.

A small upfront investment ensures your system stays clean and understandable not just next week but years into the future.

Training and Documentation

Labeling and color systems only work if people maintain them. That’s why training and documentation are vital. Your IT team should be onboarded with your labeling standards, have access to visual guides, and understand the importance of following these systems closely. Periodic checks and refresher training sessions help keep everyone aligned.

Documentation should include:

- A map of your rack or network topology.

- Standards for label naming conventions.

- The color coding system with definitions for each category.

- A history of changes, removals, or additions to the cabling infrastructure.

Future-Proofing Through Smart Organization

As your organization grows, your IT infrastructure will likely expand and evolve. What may start as a small, manageable network can quickly balloon into a multi-switch, multi-rack ecosystem. Starting smart with good cable labeling and color coding ensures that your closet stays efficient and understandable over time.

It also prevents “spaghetti syndrome”—the notorious entangled mass of unlabeled and indistinguishable cables that makes even the most experienced techs sigh. Clear labels and thoughtful use of color create a network that’s not only functional but also professional and future-ready.

Conclusion

In IT, the small things often have the biggest impact. Cable labels and color coding may seem like an afterthought, but when used right, they streamline operations, reduce risk, cut troubleshooting time, and make your IT closet a place of efficiency instead of chaos.

Take the time today to label, color code, and document your systems. Your future self—and every technician who comes after you—will thank you.